Factory supply Neutral protease enzyme for tobacco industry reducing leaf cigarette protein content

Product Description

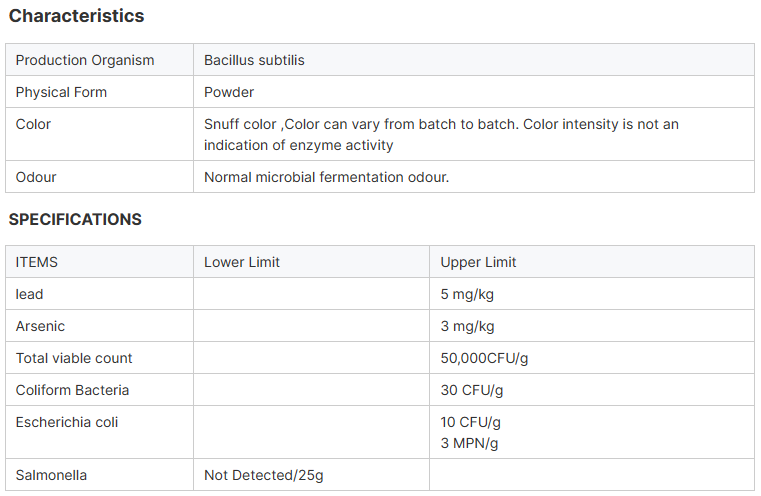

Neutral protease is produced by Bacillus subtilis through deep liquid fermentation, ultrafiltration and other processes.It can catalyze the hydrolysis of protein to produce free amino acids and peptides in neutral or weak acid or alkaline environment. Due to the advantages of high catalytic reaction speed, mild conditions and easy control of the reaction, neutral protease has been widely used in industry.

Function

1.Adding protease to decompose the protein in tobacco leaves can reduce the burning quality of tobacco, reduce the pungency, irritant and bitter taste, and improve the grade of tobacco leaves.

2.It can effectively enrich the aroma of tobacco, improve the texture of smoking, and reduce the inherent flavor of cokeand miscellaneous gas, so that the aroma permeability is better, and can coordinate the smoke temperament, reduce the flavor of coke.

3.The internal chemical composition of tobacco leaves is more harmonious and the sensory quality of tobacco leaves is improved.

Application Method

Enzyme dosage: the general recommended dosage is 0.01-3kg enzyme preparation per ton of raw materials.Smoke the stem of tobacco leaves and tear them into sheets;Weigh a certain amount of protease to prepare a certain concentration of solution.According to the setting of applying amount, a certain amountof enzyme preparation solution was measured and sprayed evenly on the experimental tobacco leaves with self-made feeding equipment. The tobacco leaves were put into a constant temperature and humidity chamber for enzymatic hydrolysis under the set experimental conditions.

The treated tobacco leaves were inactivated at 120℃, cut into shreds and set aside. Due to the difference of application field and raw material composition and process parameters of each factorythe actual adding mode and adding amount of this product should be determined by test.

Storage

|

Best Before |

When stored as recommended, the product is best used within 12 months from date of delivery. |

|

Storage at |

0-15℃ |

|

Storage Conditions |

This product should be stored in a cool and dry place in sealed container, avoiding insolation, high temperature and damp. The product has been formulated for optimal stability. Extended storage or adverse conditions such as higher temperature or higher humidity may lead to a higher dosage requirement. |

Related Products:

Newgreen factory also supplies Enzymes as following:

| Food grade bromelain | Bromelain ≥ 100,000 u/g |

| Food grade alkaline protease | Alkaline protease ≥ 200,000 u/g |

| Food grade papain | Papain ≥ 100,000 u/g |

| Food grade laccase | Laccase ≥ 10,000 u/L |

| Food grade acid protease APRL type | Acid protease ≥ 150,000 u/g |

| Food grade cellobiase | Cellobiase ≥1000 u/ml |

| Food grade dextran enzyme | Dextran enzyme ≥ 25,000 u/ml |

| Food grade lipase | Lipases ≥ 100,000 u/g |

| Food grade neutral protease | Neutral protease ≥ 50,000 u/g |

| Food-grade glutamine transaminase | Glutamine transaminase≥1000 u/g |

| Food grade pectin lyase | Pectin lyase ≥600 u/ml |

| Food grade pectinase (liquid 60K) | Pectinase ≥ 60,000 u/ml |

| Food grade catalase | Catalase ≥ 400,000 u/ml |

| Food grade glucose oxidase | Glucose oxidase ≥ 10,000 u/g |

| Food grade alpha-amylase

(resistant to high temperatures) |

High temperature α-amylase ≥ 150,000 u/ml |

| Food grade alpha-amylase

(medium temperature) AAL type |

Medium temperature

alpha-amylase ≥3000 u/ml |

| Food-grade alpha-acetyllactate decarboxylase | α-acetyllactate decarboxylase ≥2000u/ml |

| Food-grade β-amylase (liquid 700,000) | β-amylase ≥ 700,000 u/ml |

| Food grade β-glucanase BGS type | β-glucanase ≥ 140,000 u/g |

| Food grade protease (endo-cut type) | Protease (cut type) ≥25u/ml |

| Food grade xylanase XYS type | Xylanase ≥ 280,000 u/g |

| Food grade xylanase (acid 60K) | Xylanase ≥ 60,000 u/g |

| Food grade glucose amylase GAL type | Saccharifying enzyme ≥ 260,000 u/ml |

| Food grade Pullulanase (liquid 2000) | Pullulanase ≥2000 u/ml |

| Food grade cellulase | CMC≥ 11,000 u/g |

| Food grade cellulase (full component 5000) | CMC≥5000 u/g |

| Food grade alkaline protease (high activity concentrated type) | Alkaline protease activity ≥ 450,000 u/g |

| Food grade glucose amylase (solid 100,000) | Glucose amylase activity ≥ 100,000 u/g |

| Food grade acid protease (solid 50,000) | Acid protease activity ≥ 50,000 u/g |

| Food grade neutral protease (high activity concentrated type) | Neutral protease activity ≥ 110,000 u/g |

factory environment

package & delivery

transportation